U.S. DOE Awards Grants for PV Manufacturing and Installation Innovation

$71 million awarded to 18 projects in 10 US States to address gaps in the domestic solar manufacturing open new markets for solar technologies such as dual-use photovoltaic (PV) applications, including building-integrated PV and agrivoltaics

Floating Offshore Wind Turbines Explained

Overview of Floating Offshore Wind - National Renewable Energy Laboratory Webinar - March 17, 2020

$125.5 Million Solar Technologies R&D Funding Opportunity Announced by US-DOE

DOE describes the categories of Photovoltaic (PV) and Concentrating Solar Power (CSP) research & development proposals which will qualify for grant funds. Linecurrents reviews two CSP generating stations which were US Department of Energy loan guarantee recipients in the last decade.

Lightning Science and Wind-Turbine Electric Generator Protection

A celltower in Switzerland is struck by lighting more than 100 times per year. Scientists collect data there which may lead to lightning-resistant wind-turbine electric generator designs.

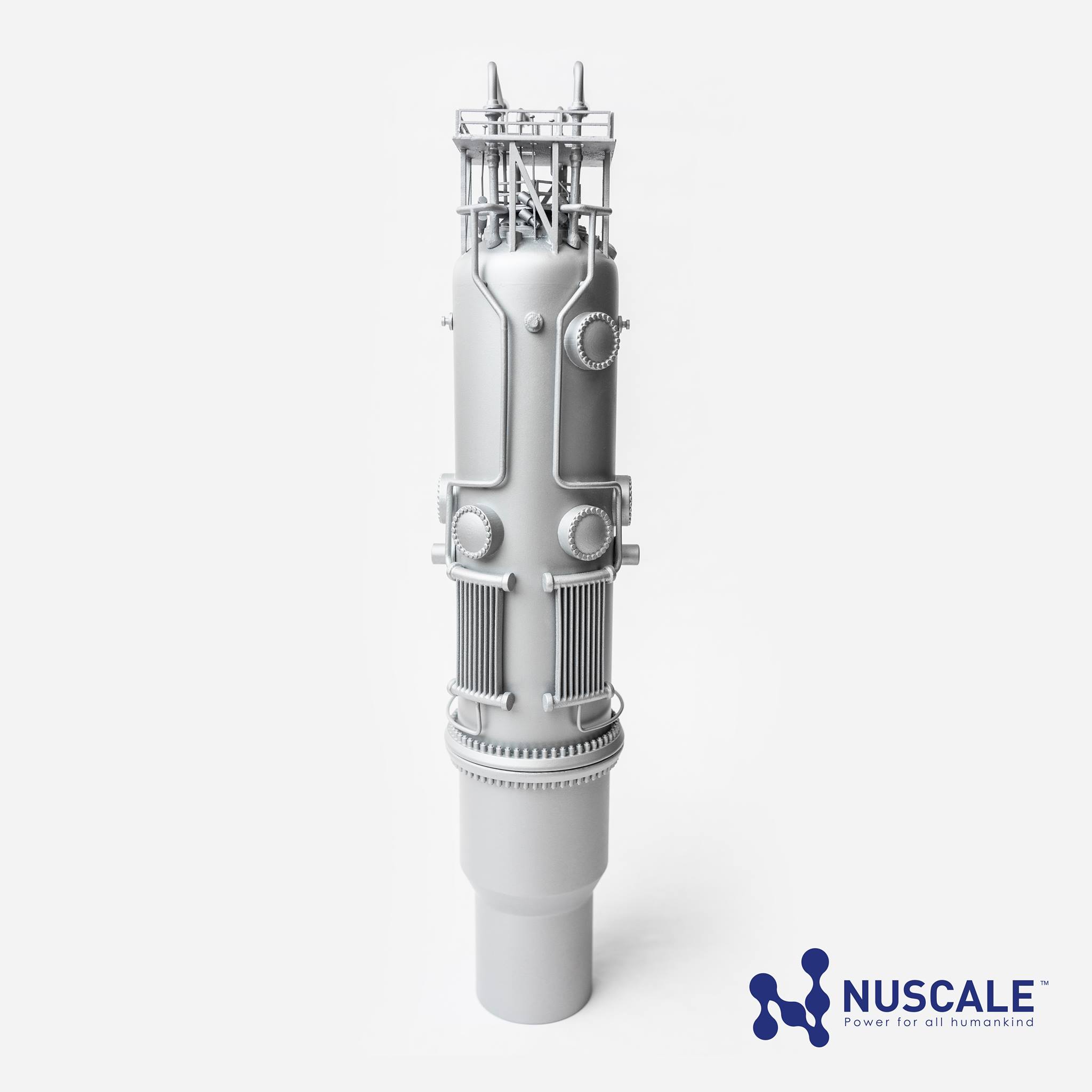

Nuclear Regulatory Commission Issues Tennessee Valley Authority Initial Approval for Small Modular Reactor Powerplant Site

Pre-assembled small modular nuclear reactor for electricity generation advances in site and design regulatory approval process..